Installing Solar on Lightweight Roofs,Lightweight roofs are widely used across industrial warehouses, logistics centers, stadiums, public buildings, commercial facilities, and modular or temporary structures. While these roofs offer lower construction costs and faster installation, they also come with a major challenge:

30–50% of lightweight roofs cannot safely support traditional rigid solar panels.

This problem is not limited to structural load. Lightweight roofs often feature:

Waterproof membranes (TPO/PVC)

Thin metal decks

Insulated sandwich panels

FRP composite roofs

Curved or uneven geometries

Aging structures not designed for point loading

Many building owners want solar, but they fear roof damage, membrane puncture, warranty invalidation, and long-term reliability issues. On the installer’s side, ignoring roof weight limits, drainage paths, or panel compatibility can put the entire project at risk.

To ensure a safe and successful installation, here are the Top 5 things you must know before installing solar on lightweight roofs—plus how flexible lightweight modules like the PA219 series help unlock new possibilities.

Know Your Load Limit – Structural Assessment Comes First

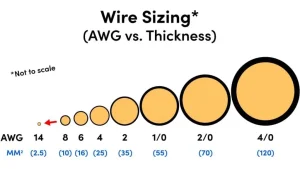

Before choosing panels, understanding your roof’s maximum load capacity is essential. Lightweight roofs typically support 10–25 kg/m², which becomes a major constraint when using conventional glass modules that weigh:

18–22 kg/m² for standard glass solar panels

Additional 3–5 kg/m² for mounting rails and clamps

This means a traditional installation can easily exceed safe limits.

The New Approach: Measure in W/kg, Not W/m²

While most solar designers focus on Watts per square meter, lightweight roofs are restricted by kilograms per square meter. Therefore, a better metric is Watts per kilogram (W/kg)—how much solar capacity can be installed per unit of weight.

| Panel Type | Weight (kg/m²) | Output (W/m²) | W/kg (Higher = Better) |

|---|---|---|---|

| rigid solar panel | 20 | 200 | 10 |

| PA219 flexible solar panel | ≈3.2 | 190 | 59 |

What This Means in Real Projects

If a roof can support 15 kg/m²:

A glass module system might allow 150–160 W/m²

A PA219 lightweight system could allow 550–750 W equivalent capacity within the same allowable load

This load-to-power advantage—4–6× more capacity—makes lightweight modules the only practical option for many rooftops.

PA219 Data You Can Highlight

Approx. 3.0–3.2 kg/m², no glass, no aluminum frame

70–85% weight reduction vs. traditional modules

Eliminates risk of micro-cracks caused by roof movement

Structural assessment should always be the first step. But choosing ultra-light modules dramatically extends what is possible on constrained roofs.

Understand the Roof Material – Compatibility Determines Reliability

Lightweight roofs vary widely in surface texture, flexibility, waterproofing layers, and expansion behavior. Choosing the wrong installation method can lead to water ingress, membrane damage, or premature failure.

Common Lightweight Roof Types

Metal sheets (corrugated, trapezoidal, standing seam)

TPO or PVC waterproof membranes

Bitumen and modified bitumen roofs

FRP / composite roofs

Curved or arched structures

Each material demands specific installation considerations.

How to Match Components to Your Roof Type

Below is a compatibility matrix using PA219 flexible modules:

| Roof Material | Adhesive Installation | Mechanical Fixing | Suitability | Notes |

|---|---|---|---|---|

| Metal roof | ✔ | ✔ | ★★★★★ | Clean surface before bonding; avoid penetrating insulation |

| TPO / PVC membrane | ✔ | ✖ | ★★★★ | Use membrane-safe adhesives; preserve waterproofing warranty |

| Bitumen | ✔ | ✖ | ★★★ | Ensure heat-resistant adhesive under high sun temperatures |

| FRP / composite roof | ✔ | ✔ | ★★★★★ | Excellent adhesion; ideal for curved surfaces |

| Arched / curved roofs | ✔ | ✖ | ★★★★★ | PA219 bend radius ideal for stadiums, canopies, EV shelters |

Real-World Applications

Historical buildings → No penetrations, minimal added load

Large-span metal warehouses → Load limits avoid traditional solar

Transportation hubs → Curved roofs + strict fire/wind standards

Modular or temporary buildings → Need lightweight, removable systems

Choosing a module designed for material compatibility is crucial—and PA219’s flexible, frameless, lightweight design provides a wider installation envelope than rigid modules.

Certified PV Technologies – Safety, Reliability & Compliance

Lightweight roofs require technologies that are not only light but also certified, tested, and safe under real-world stress conditions.

Key Certifications and Tests to Consider

IEC 61215 & IEC 61730

UL 61730

Fire safety classification

Wind load and mechanical load tests

Hail impact resistance

Temperature cycling and damp heat

Because lightweight roofs experience more vibration and thermal expansion, choosing the right cell technology matters.

Why Flexible Cell Technology Excels Here

Traditional glass modules face a common issue:

Micro-cracks caused by structural movement, wind, temperature swings, or installation stress.

On a flexible lightweight roof, this risk increases significantly.

PA219 flexible modules solve this problem with a glass-free design that eliminates micro-crack failure modes. Their lamination structure absorbs vibration and thermal expansion without compromising electrical performance.

Performance Over Time: Degradation Curve Comparison

Glass modules may suffer 5–20% additional long-term loss from micro-cracks

PA219 modules maintain stable performance thanks to flexible encapsulation and lightweight design

For lightweight roofs, certified flexible technology is not optional—it is a core safety requirement.

Design Compatibility – Orientation, Drainage & Shading Matter More on Lightweight Roofs

Lightweight roofs often have low tilt angles (0–5°), large drain paths, structural beams, skylights, HVAC equipment, or irregular shapes. These factors directly impact solar performance.

Key Design Factors to Evaluate

Orientation

Minor changes in azimuth can cause 10–25% annual energy differences.

Tilt Angle

Most lightweight roofs cannot support tilt racks due to wind load and weight, so flush installation is typical.

Drainage Paths

Standing water can:

Reduce energy output

Increase dirt accumulation

Cause hot-spots in glass modules

Flexible modules avoid these issues because they lie flat and do not trap water.

Shading

Chimneys, AC units, skylights, and stadium beams can cause localized shading. Flexible modules can be cut, shaped, or arranged more freely to avoid these zones.

How PA219 Improves Lightweight Roof Design

Operates efficiently at 0° tilt

Can be installed on curved roofs with 3–5 m radius

Does not alter the original drainage design

No rail systems → reduced wind load and structural stress

Flexibility enables creative layouts around obstacles

Use Case Examples

Sports stadiums → curved geometry

Airport terminals → low tilt, strict wind load requirements

Industrial facilities → avoid complex roof obstructions

When designing for lightweight roofs, the environment matters as much as the panel.

Financial & Business Models – Evaluate ROI for Lightweight Roof Projects

Lightweight roof solar projects often involve higher engineering requirements, so evaluating financial models early is critical.

Key Questions to Consider

Is structural reinforcement required?

Is the building owned long-term or leased?

Can the roof membrane be penetrated?

Are there production downtime costs?

What is the target ROI period?

CAPEX vs PPA Models

CAPEX

Higher upfront cost but best long-term return

Typical 3–6 year payback depending on region

PPA

Ideal for large factory roofs

Zero upfront cost

Solar provider handles design, installation, and O&M

How PA219 Improves Project Economics

Avoids structural reinforcement (saving 30–60% of additional cost)

Faster installation → less business disruption

Higher W/kg efficiency enables more total installed capacity

Reduces long-term maintenance related to glass breakage or micro-cracks

Example ROI Comparison

| Scenario | Traditional Glass System | PA219 Lightweight System |

|---|---|---|

| Structural reinforcement | Required | Not required |

| Added cost | +30–60% | 0 |

| Installation time | Longer | 30–50% faster |

| ROI | 6–8 years | 3–5 years |

| Capacity (under load restriction) | Limited | 4–6× higher |

Choosing the right technology for lightweight roofs can completely change the financial outcome.

If you’re planning a solar installation on a lightweight roof, our Sungold engineering team can help you with:

A free structural pre-assessment

Roof material compatibility review

Tailored lightweight PV design

ROI modeling & financial scenarios

Certified installation guidance