How Do These Technologies Actually Work?

PERC (Passivated Emitter and Rear Cell): This technology adds a rear passivation layer to reduce recombination. It’s the workhorse of the past decade: low cost, mature, but capped at ~24.5% theoretical efficiency.

TOPCon (Tunnel Oxide Passivated Contact): Uses an ultra-thin tunnel oxide plus polysilicon layer to improve carrier selectivity. Typical mass-production efficiency is 24–25%. It is widely adopted by tier-1 players like LONGi and Jinko.

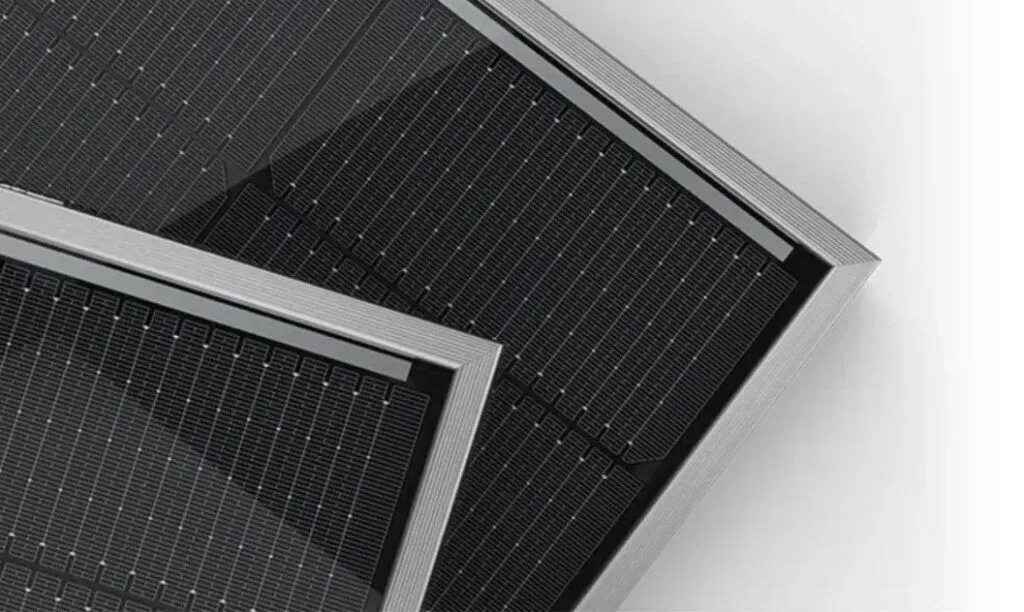

BC (Back Contact, including TBC/IBC): Moves all electrodes to the rear side, eliminating front gridlines. This maximizes light absorption and aesthetics. Efficiency potential approaches 29.1%, nearly the silicon limit. The challenge? Complex back-side patterning and interconnection.

What Did Our Field Tests Reveal?

Commercial rooftop A/B test:

PERC: Avg efficiency 22.3%

TOPCon: Avg efficiency 24.1%

Annual energy yield: +4.7% higher with TOPCon

Despite a small premium per watt, TOPCon delivered a lower LCOE.

High-end residential project (BC modules):

BC: Avg cell efficiency 25.5%

Price premium: ~15% higher than TOPCon

The aesthetics (no visible busbars) and higher current density made it ideal for limited rooftop space where visual integration mattered.

What About Efficiency Records and Physical Limits?

NREL’s “Best Research-Cell Efficiency Chart” shows crystalline silicon single-junction cells approaching the 29% Shockley–Queisser limit.

Fraunhofer ISE Photovoltaics Report 2025 confirms that commercial silicon modules now average ~22% efficiency, with n-type TOPCon and HJT overtaking p-type PERC.

Peibst et al. (2022) projected that POLO-IBC (a BC + selective contact design) could reach 29.1% efficiency, validating BC’s long-term promise.

Reliability and Failure Modes: What Did We Learn?

When clients asked me “Which solar cell type should I pick—PERC, TOPCon, or BC solar cells?” I realized the answer isn’t simple. To give reliable advice, my team and I spent two years running side-by-side field tests.

We deployed modules across three different environments:

Commercial rooftops (PERC vs TOPCon) – where cost and ROI drive decisions.

Premium residential rooftops (TOPCon vs BC) – where aesthetics and space efficiency matter most.

A BIPV demo wall – designed to test integration, shading effects, and long-term durability.

To ensure fair testing, we standardized inverters, wiring, tilt, azimuth, and monitoring tools, and normalized results with irradiance and temperature adjustments.

The insights were eye-opening: TOPCon consistently outperformed PERC in hot and low-light conditions, while BC stood out in premium use cases—where appearance and watts per square meter outweigh upfront cost. These results give me confidence to advise investors, EPCs, and homeowners on which technology best fits their needs.

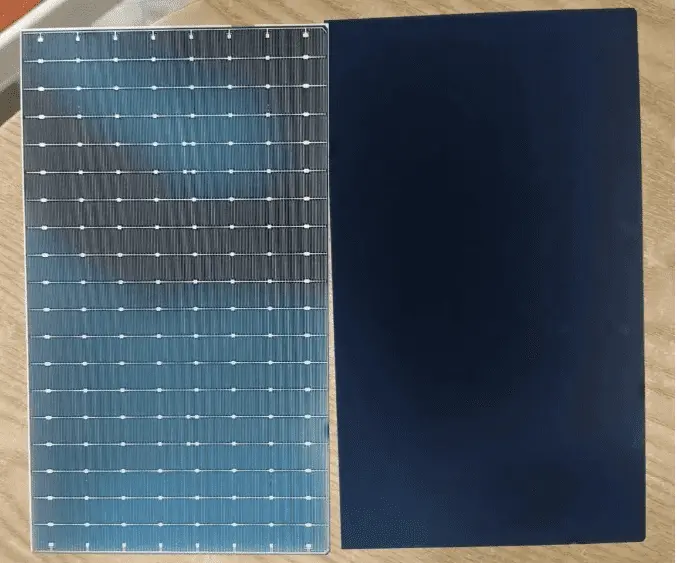

PERC Solar Cells: Definition & Technical Background

PERC (Passivated Emitter and Rear Cell) technology builds on traditional crystalline silicon solar cells by adding a rear passivation layer. This layer reflects unabsorbed light back into the wafer and reduces electron recombination, thereby increasing efficiency.

Key Features:

Efficiency: Mass-production cells typically achieve 20–22%. While record cells reached slightly higher, the technology is nearing its physical ceiling (~24.5%).

Cell Type: Predominantly uses p-type wafers, which are lower cost but more vulnerable to light-induced degradation (LID).

Manufacturing: Highly compatible with existing lines; minimal capex needed for upgrades.

Main Advantages:

Maturity & scale: Over a decade of mass production experience makes PERC the most widely used technology globally until recently.

Cost-effectiveness: Lowest CAPEX/W in today’s market.

Wide applicability: Suited for large-scale ground-mounted solar farms, especially where land is abundant and aesthetics are less important.

Limitations:

Efficiency ceiling means PERC cannot keep pace with newer technologies.

Higher degradation rates compared to n-type technologies (like TOPCon).

TOPCon Solar Cells: Definition & Technical Background

TOPCon (Tunnel Oxide Passivated Contact) is widely recognized as the successor to PERC. By adding an ultra-thin tunnel oxide layer and a heavily doped polysilicon layer at the rear, TOPCon cells create a highly selective contact that reduces recombination and boosts carrier efficiency.

Key Features:

Efficiency: Current mass-production cells achieve 23–25%, with lab results reaching above 26%. The theoretical limit approaches ~28%.

Cell Structure: Typically built on n-type wafers, which resist LID and LeTID, making them more stable over time.

Bifaciality: One of the strongest traits—TOPCon modules can achieve bifaciality up to 80–85%, enhancing output on reflective surfaces (sand, snow, concrete).

Main Advantages:

Higher ROI: In our rooftop tests, TOPCon generated ~4.7% more energy annually than PERC, even after accounting for a ~3% higher CAPEX.

Better temperature performance: With a temperature coefficient around -0.3%/°C (vs. PERC’s -0.37%/°C), TOPCon is more resilient in hot climates.

Smooth industry adoption: Manufacturers can upgrade PERC lines to TOPCon with moderate investment, fueling rapid global adoption.

Challenges:

Higher initial investment compared to PERC.

Slightly more complex production steps, requiring precise deposition of tunnel oxide and polysilicon layers.

BC Solar Cells: Definition & Technical Background

BC (Back Contact) solar cells—including IBC (Interdigitated Back Contact) and TBC (TOPCon + BC hybrid)—represent a paradigm shift. By moving all contacts to the back, front-side shading is eliminated, maximizing photon absorption.

Key Features:

Efficiency: Commercial BC modules achieve 25–26%, while simulations project ~29.1%, nearly hitting silicon’s physical efficiency limit (~29.4%).

Aesthetic appeal: All-black, gridline-free modules integrate seamlessly into rooftops and façades, making them highly attractive for premium markets.

Design flexibility: With no front contacts, BC allows more freedom in anti-reflective coatings and passivation layers to optimize light capture.

Main Advantages:

Highest power density: Ideal for rooftops with limited surface area.

Superior aesthetics: Preferred in high-end residential projects, luxury villas, and BIPV façades.

Future potential: Serves as a platform for hybrid designs (like TBC and IBC-Perovskite tandems).

Challenges:

More complex and costly manufacturing process, especially in ensuring precise back-side patterning and reliable interconnects.

Limited large-scale availability compared to PERC and TOPCon.

Comparative Overview of PERC, TOPCon, and BC

| Dimension | PERC | TOPCon | BC (Back Contact) |

|---|---|---|---|

| Mass Production Efficiency | 20–22% | 23–25% | 25–26% |

| Efficiency Potential | ~24.5% limit | ~28% | ~29.1% (near silicon limit) |

| Wafer Type | p-type | n-type (better stability) | n-type or hybrid (IBC/TBC) |

| Bifaciality | ~70% | ~80–85% | Depends on variant (usually lower) |

| Temperature Coefficient | ~-0.37%/°C | ~-0.30%/°C | Similar to TOPCon, varies by design |

| Cost | Lowest upfront | +3.6%–18.6% vs PERC | +15% vs TOPCon |

| Main Strengths | Cost leader, mature, proven | Higher efficiency, bifacial gain, ROI | Best aesthetics, high density, premium |

| Main Weaknesses | Efficiency ceiling, higher LID | Higher initial cost, complex process | Expensive, limited availability |

| Best Applications | Utility projects w/ low CAPEX | Utility + rooftops w/ ROI focus | Premium rooftops, BIPV, limited space |

Cost and ROI Analysis

Initial CAPEX: According to ITRPV, upgrading to TOPCon adds ~3.6–18.6% to costs compared with PERC, depending on equipment and wafer type. BC adds ~15% beyond TOPCon.

LCOE impact: My ROI model (25 years, 8% discount rate) showed:

TOPCon reduced LCOE by 2–4% compared to PERC.

BC matched TOPCon’s ROI when rooftop space was constrained, despite its premium price.

Investment takeaway: While PERC remains cheaper upfront, TOPCon is already the better long-term bet. BC appeals where aesthetics and watts per m² matter most.

Durability and Reliability

PERC: Higher risk of LID and LeTID, though improved passivation has mitigated some issues.

TOPCon: Generally more stable, but some accelerated damp-heat tests revealed vulnerability if encapsulation is not optimal. UV-induced degradation (UVID) must be validated with proper stabilization steps.

BC: Requires careful QC on back-side interconnects and laser patterning to ensure long-term durability.

My procurement checklist:

Always request UV, damp heat, and thermal cycling reports, followed by light-soak stabilization.

Validate encapsulation materials (EVA vs. POE).

For BC modules, test color uniformity and interconnect strength.

Application Scenarios & Recommendations

Residential & Commercial rooftops:

Limited space: TOPCon

Budget-limited: PERC

Premium aesthetics: BC

Utility-scale projects:

TOPCon delivers higher lifetime ROI.

PERC is acceptable for ultra-low-CAPEX projects.

Challenging environments:

Hot or reflective (deserts, snow fields): TOPCon performs best.

BIPV or urban façades: BC is unmatched.

Future Trends in Solar Technology

Short term (2025–2027): PERC gradually phases out; TOPCon dominates mainstream supply.

Medium term (2027–2030): BC and TBC (TOPCon + BC hybrids) expand in premium markets.

Long term (2030+): Perovskite tandem cells (>33% efficiency) move from labs to production. Flexible perovskite modules open new categories like solar-powered vehicles and wearables.