Fuel costs, battery failures, and refrigeration downtime are three of the biggest headaches for long-haul fleets. Every hour of idling a diesel engine just to keep a trailer cool burns fuel, wears out components, and increases CO₂ emissions.

This is where solar panels for semi trucks are changing the game. By turning the roof of a trailer into a power plant, fleets can:

Supply clean power to refrigeration units

Keep liftgates, telematics, and lighting running

Protect batteries during long parking periods

Reduce idling and total cost of ownership (TCO)

In this guide, we’ll walk through how a solar system for semi trucks works, what technology options you have, how much it costs, and how Sungold Solar’s flexible modules and anti-shading solar technology help real fleets upgrade to cleaner, smarter operations.

Why Solar Panels for Semi Trucks Are Growing

Lorem ipsum dolor sat amet,consectetur adipiscing elit。 Ut elittellus,luctus nec ullamcorper mattis,pulvinar dapibus leo。

Heavy-duty transportation has traditionally been locked into diesel. But in the last few years, several forces have pushed fleets to look for alternatives:

Rising diesel prices and volatile fuel markets

Stricter anti-idling regulations (EPA, CARB, local city rules)

Growth of electric and hybrid trucks

Corporate ESG targets and customer pressure to decarbonize

Refrigerated trailers are especially suitable for solar panels for trucks because:

A 48–53 ft trailer offers 20–40 m² of unused roof area

Cold chain operations require 24/7 energy

Many trucks spend hours parked at depots, ports, or borders

As a result, more OEMs and fleet operators are integrating truck solar panel systems as standard or optional packages rather than experimental add-ons.

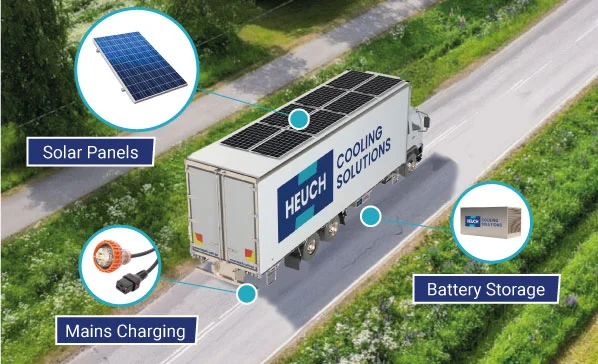

How a Solar System for Semi Trucks Works

A typical solar system for semi trucks includes:

Solar panels – flexible or rigid, mounted on the trailer roof, side fairings, cab, or liftgate.

MPPT charge controller – maximizes energy harvest and protects the battery.

Battery bank (12V / 24V / 48V) – stores energy for use when sunlight is low or the engine is off.

Power distribution & protection – fuses, breakers, wiring harnesses, sometimes an inverter for AC loads.

Optional axle regeneration – some systems combine solar with axle-based energy recovery when braking.

Energy Flow in Real Operation

In real fleet operations, a solar panel semi truck typically runs in three modes:

Driving mode

Alternator powers main vehicle loads.

Solar panels assist by charging the auxiliary battery and powering refrigeration or electronics.

Result: less alternator load, lower fuel consumption.

Parking / overnight mode

Engine is shut down to avoid idling.

Solar energy plus the battery bank keep the refrigeration unit, telematics, and lights running.

Result: no idling fines, no wasted fuel.

Regenerative mode (if available)

When going downhill or braking, the axle regeneration system charges the same battery bank.

Solar + regen work together for higher total net energy.

Typical Applications on Semi Trucks

On modern fleets, truck solar panel systems are used for:

Refrigerated trailer units (TRU)

Liftgate power

Battery maintenance during storage or layover

GPS, telematics, EBS, cameras, LoRa/5G sensors

Interior LED lighting and safety beacons

Auxiliary HVAC in sleeper cabs

Range extension on electric or hybrid semi trucks

Solar Panel Technology Options for Semi Trucks

Flexible Solar Panels – PA219 / PA621 Series

Flexible solar panels are ideal for semi truck trailers because they are:

Lightweight – typically 2–3 kg/m², very friendly for lightweight roofs and refrigerated boxes.

Low-profile – mounted flush with the roof, minimizing wind resistance.

No drilling – bonded using industrial adhesives, preserving the integrity and warranty of the roof.

Shock & vibration resistant – designed for long-haul highway conditions.

Sungold’s PA219 and PA621 series are designed specifically for transportation, RV and refrigerated trailers. With anti-shading solar technology, these modules keep generating power even when A/C units, side fairings or cargo cast partial shadows.

High-Efficiency Rigid Panels – SGM Series

When maximum power density is required—such as for high-demand refrigeration units or electric semi-trucks—rigid modules like SGM 420W are a strong choice:

Monocrystalline efficiency up to around 23%

Composite backsheet and lightweight design

Higher power per square meter to fully utilize limited roof space

Suitable for fleets operating primarily in high-insolation regions

Anti-Shading Solar Technology

Real trucks rarely enjoy perfect, uniform sunlight. Shadows from refrigeration units, rooftop rails, even accumulated dust can reduce power if the system is not designed properly.

Sungold’s anti-shading solar technology uses:

Optimized cell string layout

Distributed bypass diodes

Multi-busbar cell design

to ensure that only the shaded section is bypassed instead of dragging down the whole module. This is critical for semi trucks that constantly drive under bridges, trees, road signs, or park next to tall buildings.

Key Benefits of Solar Panels for Semi Trucks

By combining solar panels for semi trucks with smart battery management, fleets can:

Cut engine idling used purely for cooling

Reduce alternator load during driving

Extend battery life from 1.5–2 years to 4+ years

Avoid many roadside jumpstarts and service calls

Over a typical year, a refrigerated trailer using a truck solar panel system can save thousands of dollars in fuel and maintenance—often paying back the system investment within 9–18 months.

Operational Reliability

Solar-assisted systems provide multiple layers of redundancy:

Cooling can continue during driver rest breaks without idling

Liftgates stay powered even after repeated loading cycles

Telematics and GPS remain online during long dwell times

Batteries are kept at healthy charge levels, preventing deep discharge damage

This translates into fewer missed deliveries, fewer rejected loads, and more reliable cold chain performance.

Installation & Cost Considerations

Installation Approaches

Flexible panels (PA219 / PA621)

Bonded directly to the roof skin with industrial adhesive

No roof penetration, simple cable routing

Minimal impact on vehicle height and aerodynamics

Rigid panels (SGM 420)

Mounted on low-profile brackets or frames

Suitable where maximum power per square meter is required

How to Choose the Right Solar System for Your Fleet

When selecting solar panels for semi trucks, consider:

Energy demand – refrigeration hours per day, liftgate cycles, telematics loads.

Available roof area – can you fit 600 W, 1 kW, or more?

Vehicle routes – high-sun regions vs cloudy climates.

Parking patterns – long overnight parking benefits more from solar.

Roof structure & weight limits – flexible vs rigid panels.

Budget & payback expectations – how fast should the investment return?

Sungold’s engineering team can help design a matched system based on your duty cycles and trailer types.

Real-World Application Scenarios

Refrigerated food distribution – city-to-city cold chain with frequent stops.

Cross-border transport – long border queues where idling is restricted.

Frozen seafood logistics – strict temperature control and long dwell times at ports.

Electric or hybrid semi trucks – using solar to support HVAC, electronics, and partial traction battery top-up.

The Future of Solar Panel Semi Trucks

Looking ahead, solar panels for trucks will become more integrated:

Trailer roofs designed from the factory as solar-ready composite skins

Smarter energy management software optimizing solar, axle regen, and grid charging

Closer integration with OEM electric powertrains

Standardization of solar specifications across fleets

FAQ

Q:What are the main benefits of installing solar panels for semi trucks?

A:They reduce fuel consumption by cutting idling, extend battery life, provide continuous power to refrigeration units and liftgates, and help fleets meet sustainability and anti-idling regulations.

Q:How much fuel can a solar system for semi trucks save per year?

A:Actual savings vary by route and usage, but many refrigerated fleets report thousands of dollars in fuel and maintenance savings per trailer each year, with typical payback periods of 9–18 months.

Q:Can solar panels run a refrigerated trailer by themselves?

A:In most cases, solar panels for semi trucks are designed as an assist system. They greatly reduce diesel usage and idling, but for full cooling capacity they typically work together with the engine or battery-powered refrigeration unit.