Solar panel connectors play a crucial role in the efficient functioning of solar energy systems. They facilitate the secure and reliable connection between solar panels, enabling the smooth flow of electricity.

What are solar panel connectors?

A solar panel connector is a specialized device that enables the connection between solar panels and other components of a solar energy system, such as inverters or batteries. These connectors provide a safe and efficient way to transfer electrical power generated by solar panels.

Why are connectors important for solar panels?

Firstly we need to know the importance of solar energy and the benefits of solar energy. This can be learned from the article by Solar Energy Technologies Office. Solar panel extension cables and PV connectors are essential for solar panels as they ensure the integrity of the electrical connection. Reliable connectors minimize power losses, enhance system performance, and maintain the safety of the solar installation. They also facilitate easy maintenance and troubleshooting by allowing the disconnection and reconnection of solar panels when required. Currently, there are various types of solar panel connectors available throughout the market.

What types of connectors are used for solar panels?

3.1 MC4 connectors: Industry standard

MC4 (Multi-Contact 4) connectors are widely regarded as the industry standard for solar panel connections. They are known for their reliability, compatibility, and durability. MC4 connectors feature a plug-and-socket design, allowing quick and easy connections. Due to their efficiency and wide availability, these mc4 solar connectors have become ubiquitous in the solar industry. MC4 Connector with IP67 and IP68 Waterproof Rating.

3.2 MC3: Obsolete technology

MC3 connectors were used in the past, but they have become outdated and are no longer commonly used in modern solar installations. MC3 connectors had similar features to MC4 connectors solar but lacked the same level of compatibility and reliability.

3.3 Helios H4

Helios H4 connectors are renowned for their high current-carrying capacity and robust construction. They are designed to handle larger solar systems and heavy-duty applications. Helios H4 connectors offer excellent resistance to extreme weather conditions and provide secure connections.

3.4 SolarLok

SolarLok connectors, developed by Amphenol, are known for their innovative design and high-performance features. They offer a compact size, easy installation, and reliable connections. SolarLok connectors are suitable for various solar applications and can withstand harsh environmental conditions.

3.5 Radox

Radox connectors, manufactured by HUBER+SUHNER, are specifically designed for demanding solar applications. They feature a high level of mechanical and electrical durability, making them suitable for installations that require long-term reliability. Radox connectors provide secure connections in challenging environments.

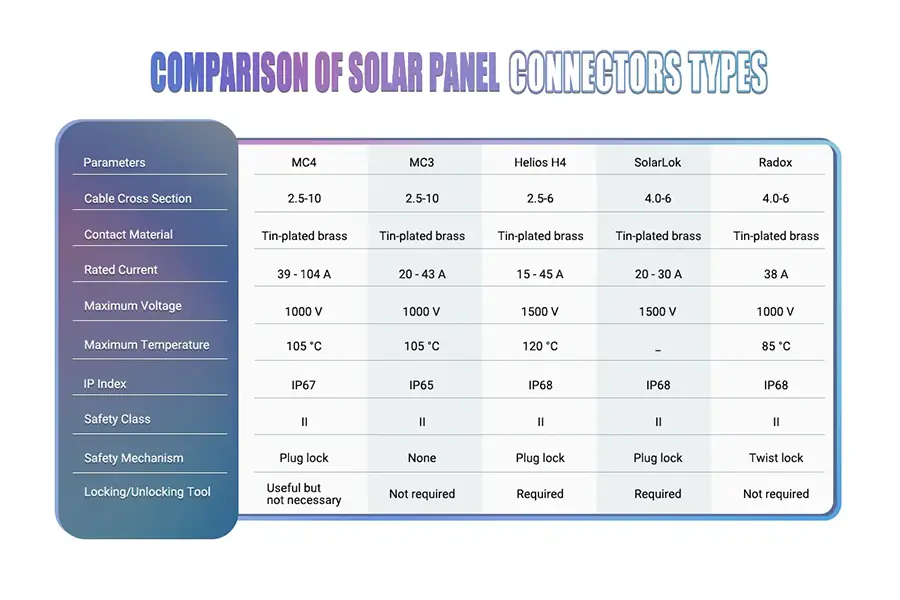

What is the difference between the connector types?

Please refer to the accompanying diagram for a visual representation of the differences between the five connector types: MC4, MC3, Helios H4, SolarLok, and Radox.

How do I choose the right solar panel cable connectors /solar panel connector?

When selecting solar panel connectors and solar cables, several factors need to be considered to ensure system reliability and performance. Here are some of the considerations Sungold suggests for you:

a. Maximum Current: When selecting a connector make sure that its maximum current rating is greater than the current rating of the solar panel to avoid any potential conductivity issues.

b. Maximum Voltage: It is critical to check the maximum voltage that the solar panel connector can withstand without damage or failure. Make sure that the maximum voltage rating of the connector is higher than the maximum output voltage of the solar panel to prevent voltage issues.

c. Maximum Temperature: Solar panels need to be used at high temperatures for long periods, it is recommended to choose solar panel cables that are resistant to high temperatures and harsh weather conditions.

d. Contact Material: The performance and durability of the connector depend greatly on the material used. Preference is given to solar panel cables made of durable, high-quality materials such as PCs.

e. Contact resistance: Select solar panel cables with low contact resistance to maximize the output efficiency of the solar panel.

f. Ingress Protection (IP) rating: You also need to make sure that the solar panel connector has adequate protection against dust and water; the higher the IP rating, the better it is for extreme environments.

How do I connect the solar panel connectors?

To connect solar panel connectors, follow these step-by-step instructions:

Step 1: Gather the required tools: You will need wire strippers, an MC4 tool: a crimping tool specifically designed for mc4 solar connectors, an MC4 cable (male and female), and the appropriate solar wires. Sungold offers 12AWG solar cables in customized lengths. Users can use it to connect Sungold 100W-400W solar panels and portable power stations.

Step 2: Turn off the system: Before starting, make sure the solar system is turned off to avoid the risk of electric shock.

Step 3: Strip Wire Insulation: Using wire strippers, carefully strip approximately 1 cm (0.4 inches) of insulation from the end of the solar wires to expose the metal conductors.

Step 4: Assemble the connector: Slide the appropriate MC4 connector housing (male or female) onto the stripped wire end. Be sure to slide on the watertight sealing gland and metal locking clip.

Step 5: Prepare Crimp Tool: Open the crimp tool and insert the MC4 crimp pins (male or female) into the designated slots. This slot will hold the pin securely in place while you perform the crimping process.

Step 6: Crimp connector pins: Insert the stripped end of the solar cable into the crimp pins secured by the crimping tool. Firmly squeeze the handle of the crimping tool to crimp the pin onto the wire, creating a strong, secure connection. Release the handle and remove the crimp pin from the tool. Gently pull on the wire to ensure a firm crimp.

Step 7: Insert the crimp pin into the connector housing: Push the crimp pin into the MC4 connector housing until it snaps into place to ensure a solid connection. You should not be able to pull the pin out easily.

Step 8: Assemble the connector: Slide the waterproof sealing gland and metal locking clip onto the connector housing. Tighten the sealing gland onto the connector housing to create a watertight seal.

Step 9: Testing Connection: After firmly connecting the crimped solar connector to the wire, connect it to the corresponding connector on the other solar wire (male to female and vice versa). The connectors should snap together, indicating a solid connection.

Five Frequently Asked Questions

Can I mix different solar panel connector types in my solar installation?

It is generally not recommended to mix different solar panel connector types in a solar installation. Each solar panel connector type is designed with specific mechanical and electrical characteristics, and using different types together may result in an unreliable or unsafe connection.

Mismatched connectors might not fit properly, leading to loose connections, increased electrical resistance, and potential hotspots, which can adversely affect the performance and efficiency of the solar system. To ensure a reliable and safe solar panel installation, it is best to use connectors of the same type throughout the system.

Are there any specific safety precautions to consider when working with solar panel connectors?

Safety is of utmost importance when working with solar panel connectors. Here are some essential safety precautions to consider:

a. Turn off the solar system: Before handling any connectors or wires, ensure the solar system is completely turned off to avoid the risk of electric shock.

b. Wear appropriate safety gear: It’s essential to wear safety glasses and gloves to protect yourself from any potential hazards during the installation process.

c. Avoid wet conditions: Work in dry conditions and avoid handling connectors with wet hands or in wet environments to prevent electrical hazards.

d. Use proper tools: Utilize tools specifically designed for working with solar connectors to ensure secure and accurate connections.

e. Double-check polarity: Pay close attention to the polarity while connecting the wires, as reversing the connections could lead to potential damage to the solar system.

f. Check for damage: Inspect the connectors and wires for any signs of damage or wear before installation. Damaged components should be replaced immediately.

g. Follow manufacturer instructions: Always adhere to the manufacturer’s guidelines and instructions for installing connectors to ensure proper and safe connections.

What are the advantages of using MC4 solar panel connectors over other types?

a. Standardization: Solar connectors mc4 are an industry standard, ensuring compatibility and widespread availability. They are widely used and accepted across various solar installations.

b. Reliability: MC4 solar panel connectors provide secure and reliable connections, reducing the risk of power loss and electrical faults in the solar system.

c. Easy installation: The plug-and-socket design of MC4 solar panel connectors allows for quick and straightforward installations, saving time and effort during the setup process.

d. Watertight sealing: MC4 solar panel connectors come with watertight sealing glands, ensuring protection against moisture and environmental elements, which is crucial for outdoor solar installations.

e. Durability: These connectors are built to withstand harsh weather conditions and UV exposure, ensuring long-lasting performance in outdoor settings.

Are there connectors suitable for high-power solar installations?

Yes, there are solar wire connectors designed to handle high-power solar installations. Solar panel connectors like Helios H4 and Radox, as mentioned earlier, are specifically engineered for demanding applications that involve higher current-carrying capacities.

These connectors are built with heavy-duty materials, ensuring reliable connections in large-scale solar installations where higher power levels are involved.

Can I install solar panel connectors myself, or should I hire a professional?

Installing solar panel connectors is a task that individuals can do with some technical knowledge and experience in electrical work. However, if you are not confident in your abilities or lack experience in working with electrical systems, it is best to hire a professional solar installer.

A qualified installer will have the necessary expertise and understanding of safety protocols to ensure a proper and secure installation.

Working with electricity can be dangerous, and it’s crucial to prioritize safety when dealing with solar electrical connectors, especially if you are unsure of the installation process. Hiring a professional can provide peace of mind and guarantee a safe and efficient solar energy system setup.

How do I know the positive and negative terminals on a solar panel?

There are two simple ways to determine the positive and negative terminals on a solar panel:

Look for markings: Most solar panels have markings on the back of the panel, usually labeled (+) or (-) or P and N. These markings indicate where the positive and negative terminals are connected. These markings indicate where the positive and negative terminals are connected.

Using a multimeter: Place the multimeter in DC voltage mode and touch the positive probe to one side of the solar panel and the negative probe to the other. The side that reads positive voltage is the positive terminal.

Final Thoughts

Solar panel connectors are essential components for establishing reliable electrical connections in solar energy systems. Understanding the different types of connectors and how to connect them properly ensures optimal system performance and safety. By following the recommended guidelines and using appropriate tools, you can confidently install and maintain solar panel connectors, contributing to the efficiency and longevity of your solar installation. Sungold’s latest article About Solar Panel Connectors – Guide 2024 is also worth a look!