Table of Contents

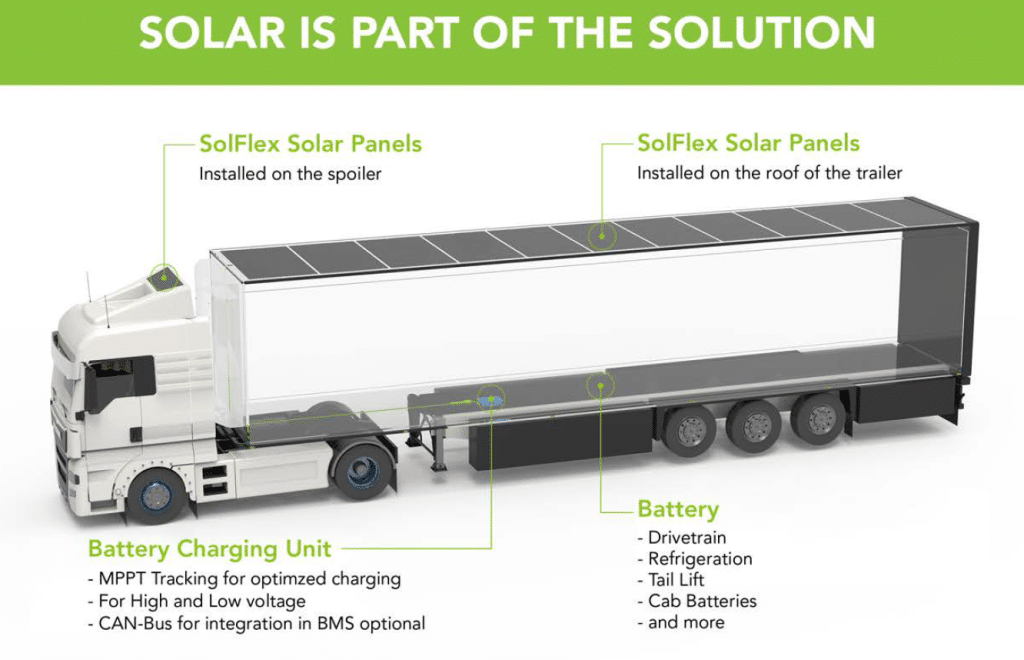

Technological advancements have propelled the photovoltaic industry, making it possible to integrate flexible, ultra-thin solar panels onto vehicle exteriors. This breakthrough improves vehicle range, increases battery efficiency, and extends life spans. Solar-powered refrigerated trailers are one of the transformative applications in heavy transport, offering energy autonomy and substantial cost savings — two critical elements for staying competitive.

Refrigerated trucks are vehicles that can benefit greatly from the installation of flexible solar panels. Not only do they have high energy consumption in order to maintain ideal refrigeration conditions, but they also have a significant amount of space available for the installation of solar systems. Traditional refrigerated trailers are equipped with single or multi-temperature cooling technologies, which allow for the transport of refrigerated products at temperatures ranging from 0° to +7°C and frozen products at -18°C. The generator is powered by a battery, just like a regular car.

How flexible panels work in solar-powered truck refrigeration?

Refrigerated trucks are among the highest energy-consuming vehicles, requiring a continuous power supply to maintain a temperature range of 0 to +7°C and, for transporting frozen foods, as low as -18°C. Flexible solar panels used in refrigerated truck transport convert sunlight into electricity during the day. A Maximum Power Point Tracking (MPPT) converter regulates the current generated by the panels, acting as the “brain” of the photovoltaic system. The converted electricity is stored in batteries, which power the truck’s Transport Refrigeration Unit (TRU) to keep it running.

While these principles underlie the basic operation of a solar system, refrigerated mobility offers a range of configurations, from hybrid to fully electric solutions.

In the second case, there are more practical ways to eliminate diesel generators and replace them with electric and sustainable systems. One option is to integrate photovoltaics with the vehicle’s axles for regenerative braking. But equally effective and autonomous is a system that includes panels, energy storage batteries, and grid connection capabilities.

Another alternative is to mount solar panels on the sides of the trailer and connect them to batteries that are sized appropriately. The configuration choice depends largely on the type of vehicle operation.

All logistics companies with a fleet of refrigerated trucks can benefit from the economic and fuel savings these configurations offer. These advantages extend to cases where the electricity generated by solar panels supplements the hybrid refrigeration system, thus acting as an adjunct to the diesel engine.

As mentioned at the outset, batteries, being the most expensive component of an electrical system, still benefit from the presence of photovoltaics. By preventing deep discharges, their lifespan is extended. With more durable batteries, the costs of replacement are further diluted over time within the operational costs that must be considered for heavy vehicles.

Solar output depends on factors like sunlight intensity, duration of exposure, temperature, and shading. But advances in technology have produced batteries so efficient that systems built with them can generate substantial power outputs, even in tight quarters. That makes them more cost-effective than ever. Batteries also bring other advantages, like no longer suffering from deep discharges or voltage fluctuations, which extends their life. That lowers maintenance costs and spreads replacement costs over a longer period, increasing the overall value and efficiency of solar-powered systems.

Which flexible solar panels are best?

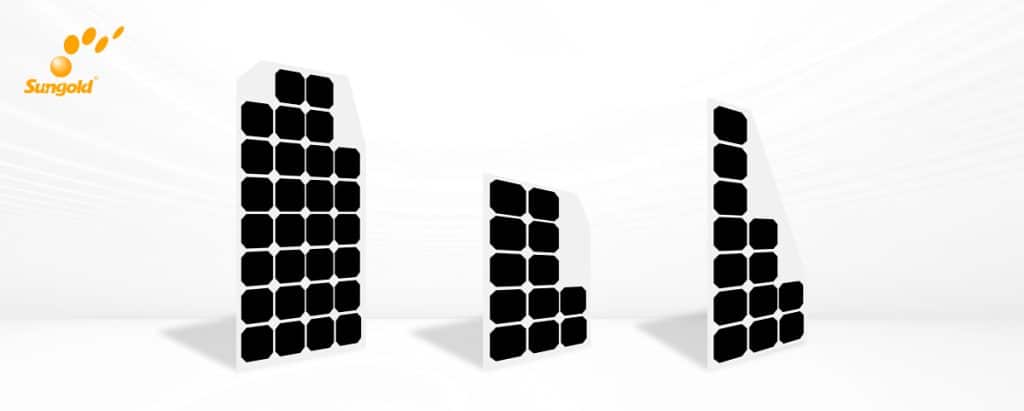

Flexible photovoltaic panels are prized for their lightness, comfort, and durability. But what customers really want is quality and customization. They want panels that can adapt to any situation and need.

Sugnold, a Chinese company, has been making these products for 16 years. It has been closely watching the mobile sector. Sugnold offers modules with different power ratings (TF panels) to best support each vehicle and its operational and energy storage needs. It also offers various models of crystalline silicon cells—the most efficient technology available—ensuring optimal performance even in the harshest environmental conditions and most demanding situations.

Efficiency and Power

One of the most intriguing technological developments in the industry is the use of flexible solar panels with solar cells that can convert over 25% of sunlight into electricity, a record efficiency level for flexible modules. The achievement is the result of more than a decade of collaboration between Sungold and Maxeon, a top technology company in solar cells that also supplies SunPower components to the market.

Durability and Weather Resistance

Panels for such applications must be robust and durable, given the constant environmental stresses of temperature swings, rain, salt mist, and accidental impacts. The Sungold TF and LEE modules, developed specifically for the marine sector, have been tested extensively by many sailors in the harshest climates. They are highly resistant to degradation.

Dimensions (Thickness and Weight)

Flexible solar panels also have an impressive thinness, less than 3 mm (for Sungold modules), which is another important factor when selecting panels. The thinner and more flexible the panels, the easier they are to integrate into different environments and create complex geometric shapes and aesthetic customizations. Being able to bend to a radius of less than one meter opens up a wide range of applications, from vehicle bodies to truck spoilers, and even boat hulls.

Pricing is always customized, but there are some factors to consider. Over the past decade, the price of photovoltaic technology has plummeted while the capacity for photovoltaic power generation has soared, making possible applications that weren’t previously economically feasible. Solar systems, for example, can now save more than 5% of fuel for trucks on a typical day. That’s a big annual savings in a fleet of 100 trucks.

Pros of Sungold TF patented technology

In the world of solar-powered refrigeration for trucking, Sungold flexible solar panels with Sungold TF technology are among the best. They convert over 22.62% of sunlight into electrical energy, meaning more power in tight spaces. That’s exceptional value for this type of module.

But Sungold TF technology offers more than high performance. The product is also flexible and light. In fact, it weighs less than 2.5 kg per square meter — compared to the 12 kg of traditional aluminum-framed panels.

Due to these features and their thickness of less than 3 mm, Sungold flexible solar panels are highly suited for the solar truck refrigeration environment, capable of adapting to every part of the vehicle’s body, not just the trailer. Additionally, compared to traditional glass modules, these panels exhibit high weather resistance (extensively tested in the marine industry) and tolerance to vehicle vibrations, making them particularly suitable for wear and damage.

How much can you save with solar-powered truck refrigeration?

In refrigerated trucks, photovoltaic systems can replace up to 85% of the diesel fuel the refrigeration units consume to keep the trailer temperature at -18 degrees Celsius. The advantages of integrating photovoltaics include reduced energy consumption and emissions, longer battery life, and increased workplace comfort. Drivers no longer need to worry about conserving energy so the battery doesn’t die. Emergency roadside assistance calls become a thing of the past. Drivers can focus more on driving. With more energy onboard, all services requiring energy — primarily heating and cooling the cabin when stationary, as well as charging and operating all electronic equipment — can be used optimally.

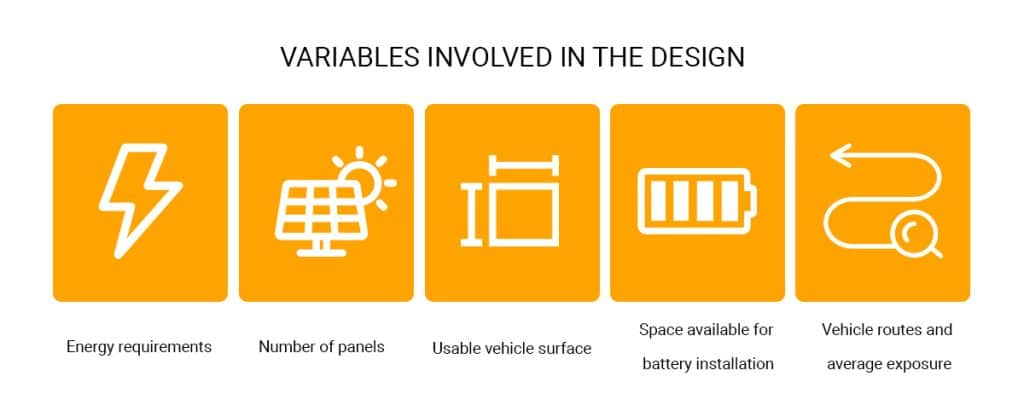

The return on investment depends on several factors, with customization and configuration of the entire system—including electronic components—significantly impacting the installation price. Therefore, technical consultation based on individual needs and vehicle types is always essential.

Over the past decade, the capacity for photovoltaic production has increased dramatically. Conversely, the cost of the technology has decreased, providing opportunities for applications that were previously economically unfeasible.

Currently, for a 5 kWp solar system, including the charge controller and accessories, the return on investment is approximately 4 years.

Installation Methods for Flexible Solar Panels

- Energy Requirements

- Number of solar panels

- Available Vehicle Surface Area

- Space Available for Battery Installation

- Vehicle Route and Average Exposure.

The advantages of solar-powered refrigerated trucks

The most obvious and tangible benefits of an entire fleet of solar-powered refrigerated trucks include lower emissions, reduced fuel consumption, and lower battery-related maintenance costs.

So, why not electrify all truck transport vehicles? While electrifying heavy transport would undoubtedly reduce pollutant emissions significantly, the lack of charging infrastructure for heavy electric vehicles currently poses a hurdle to meeting the EU’s 2050 goals. Nonetheless, photovoltaic power generation can make a significant contribution to the sustainability of transportation, thanks to the self-generated electricity provided by solar panels.

When it comes to refrigerated trucks, traditional refrigerated trailers typically use single- or multi-temperature cooling systems to transport refrigerated products (from 0 to +7°C) and frozen products (-18°C). To avoid the need for separate trailers for each temperature range, logistics companies often use vehicles that can maintain both temperatures. The diesel engine of the refrigeration unit directly drives the refrigeration compressor and, depending on the temperature to be maintained, has different fuel consumption. Switching to a hybrid system equipped with flexible solar panels can significantly reduce this consumption.

The most interesting option in the industry is a panel with back-contact cells, which can convert more than 24% of sunlight into electrical energy. That efficiency allows for high power output even in limited spaces, setting a new record for flexible modules.