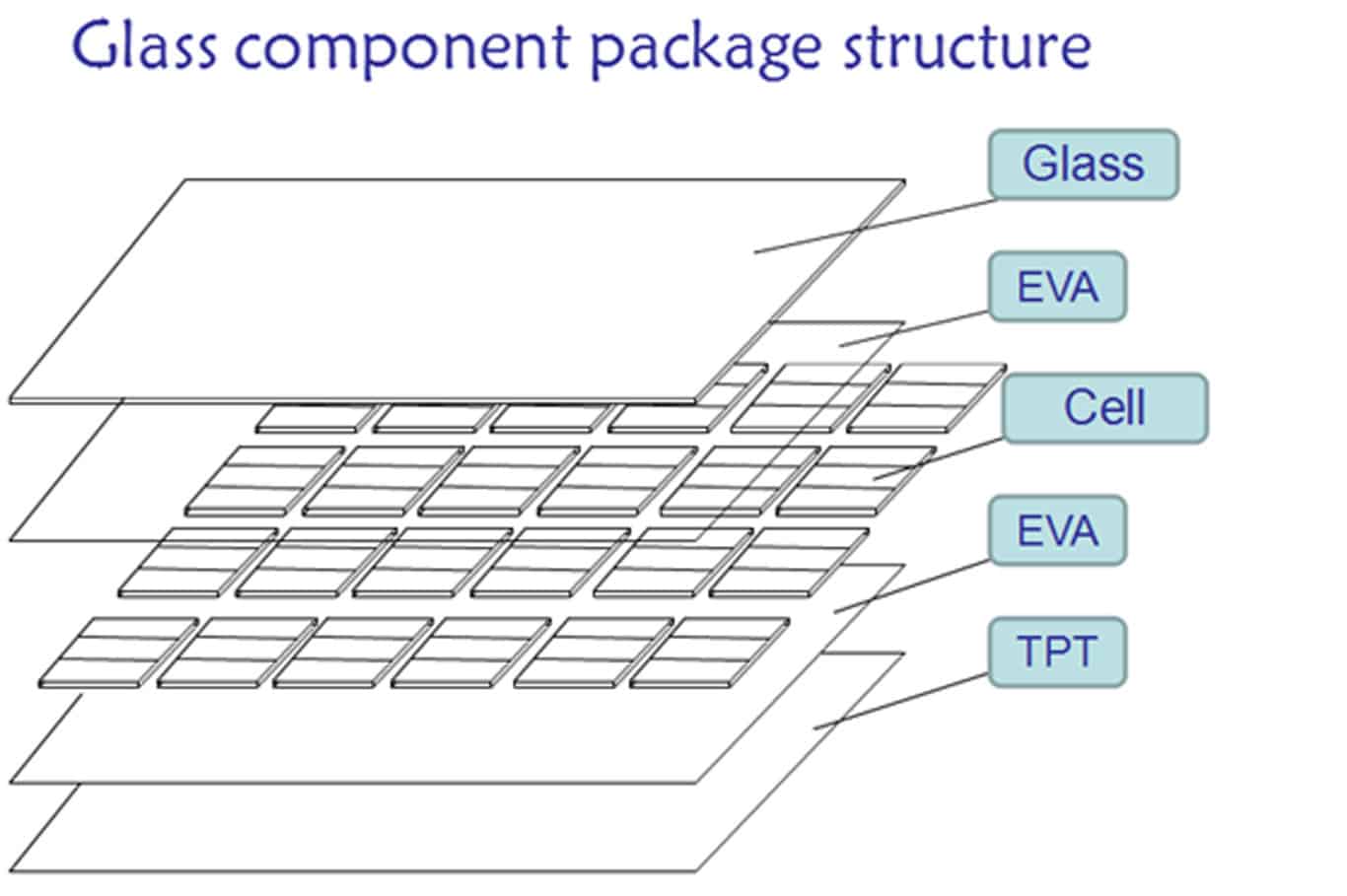

EVA choice and performance will not only affect the appearance and quality of solar panel but also affect the life of components, EVA is a flexible and adhesive performance, with good light transmission performance and anti-aging properties of the transparent colloid. It encapsulates the crystalline silicon wafer “under the cover”, and with the upper protective material glass, the lower protective material TPT (polyvinyl fluoride composite film) is composed of vacuum lamination technology to form a crystalline silicon solar panel.

EVA cross-linking degree: cross-linking degree refers to the EVA film heating linear molecules cross-linked into the mass ratio of mesh molecules. According to the theoretical analysis, the higher the cross-linking degree, the higher the light transmittance of EVA, the higher the overall output power of the module, the adjustment process parameters of the laminated process, EVA up to 95% -98%.

But the problem has arisen, the fact that the higher the degree of cross-linking in the future application of the components of the chances of cracking the greater the degree of cross-linking will be low with the glass, the backplane delamination, resulting in internal circuits together with their own machinery Performance degradation. At present, many manufacturers recommend the cross-linking degree of about 85% for the best, and different manufacturers of EVA characteristics are not the same, you need to adjust the parameters of the laminate to meet the requirements of different EVA cross-linking.

EVA Matching degree: EVA itself has a certain cut-off of ultraviolet light, it absorbs ultraviolet light through EVA itself and converts it into heat. EVA cut off the high and low direct impact on the absorption of ultraviolet light. In order to allow the battery to better absorb ultraviolet light, glass surface EVA is made of a low cut-off material, in order to enhance the utilization of ultraviolet light, the back panel surface with high cut-off EVA can not be irradiated on the battery chip UV light reflection Back to the battery for the second use. If the use of high and low cut-off, high cut-off EVA used in the glass surface, will reduce the light transmission, reduce the absorption of light on the battery, reducing the efficiency of the power generation unit. Low cut off on the back panel, can not effectively reflect the light to reduce the absorption of light on the battery, reduce the efficiency of the power generation unit, and because it can not effectively block the light, the UV light will directly irradiate the backplane, the back will turn yellow, increase The aging speed affects the quality of the components.

EVA in the course of the precautions and consequences:

1. The film can not contact the outside air for a long time

Performance gradually reduced, about 3 days will not be fully cross-linked, resulting in the glass, the back plate to produce layered, positioning tape at the drum package; welding belt with black; EVA yellow and other appearance of the quality category.

2. Environmental room temperature 30 ℃ humidity above 65%

Will cause quality deterioration and size changes, adhesive between the film.

3. If the heating to 170 ℃ or more, will cause the quality of the resin itself deterioration (decomposition).

4. Can not touch the film directly by hand

Hand oil and hand cream will cause quality deterioration and poor adhesion, discoloration.

5. Avoid contact with water, oil, organic solvents, and pharmaceuticals

Will cause quality deterioration, poor bonding, resulting in bubbles.

6. Can not be used in windows open factories, garbage and dusty places

Will cause low adhesion, the battery power is insufficient.

7. Must be laminated at a certain room temperature

The hot plate temperature of the lamina-tor changes, which can cause insufficient cross-linking or excessive heating.

The Sungold solar panels in this one to do a good job, with strict standards of implementation, strict material inspection system and strict quality supervision system so as to ensure that we give you 25 years of life warranty commitment.