What is polyvinyl butyral/PVB?

Polyvinyl butyral (PVB) is essentially a resin (polyvinyl butyral resin) that is typically used in applications requiring strong adhesion, optical clarity, adhesion to many surfaces, toughness and flexibility.

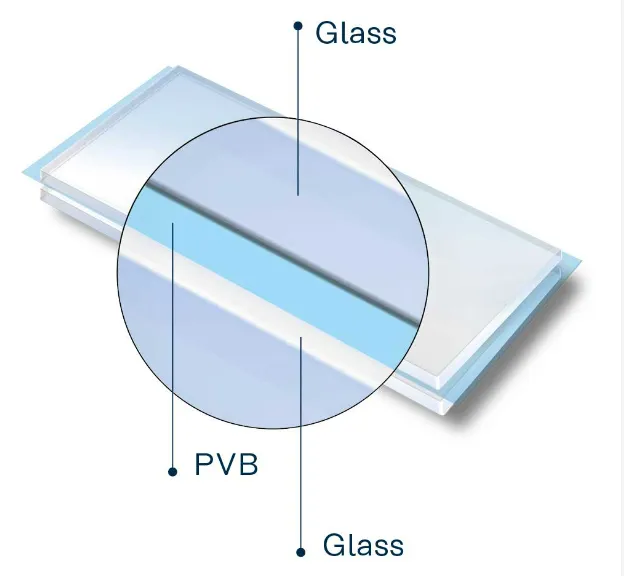

It is commonly used as an interlayer in the production of safety glass and laminated glass products.

Some types of interlayers are made from other materials, such as EVA (ethylene vinyl acetate.) PVB interlayers offer unique advantages in terms of adhesion to glass, penetration and impact resistance.

Because of its shatterproof properties, PVB interlayer for laminated glass is used in many applications where safety and security are required, such as automotive windshields, side windows and doors, and architectural glazing.

In the automotive industry, the use of laminated glass for windshields is mandatory in almost all countries, including the United States, Europe and Japan.

With today’s need for brighter and more open spaces, the role of glass in comfort, design and safety is expanding. polyvinyl butyral interlayer is attracting attention as a technology that enhances the possibilities of glass.

In the field of solar technology, polyvinyl butyral PVB is used as an encapsulation layer in solar panels/polyvinyl butyral interlayer.

Advantages of PVB

- Meets all safety and quality standards for laminated safety glass.

- Stronger adhesion of the glass during the lamination process and greater resistance to defects.

- Laminate (glass, cell, connecting material) is more compact.

- Long-term light and temperature stability of the module system based on experience with laminated safety glass.

- Combined with other features in PV module glazing, e.g. acoustic PVB, colored PVB, to achieve design features.

- Thinner glass thickness compared to the use of other encapsulation materials, resulting in lighter unit weight and structural support advantages.

- UV Blocking – Blocks 99% of UV rays.

- Design – gradients or colors in different film thicknesses.

- Meets standard specifications for structural and safety glass definitions.

Role of PVB in Solar Panels

In solar panels, PVB polyvinyl butyral plays a key encapsulation role and its main function is to enhance the durability, protection and overall performance of the solar panel.

Encapsulation process

PVB is a transparent plastic layer that is typically used between glass to provide a bonding and protective layer. In solar panels, the polyvinyl butyral film sits between the glass in front and the backsheet in the back, tightly encapsulating the solar cells to form a strong composite structure. This configuration not only enhances the mechanical strength of the panel, but also ensures its water and dust resistance.

Enhanced durability

The high weather ability of PVB films ensures that solar panels are resistant to harsh external environments, including intense UV rays, temperature changes and humidity.These properties of Polyvinyl butyral PVB help to prolong the service life of solar panels and minimize degradation of performance due to environmental factors.

Protecting photoelectric conversion efficiency

PVB’s excellent light transmission is another key factor in its use in solar panels. It effectively allows sunlight to penetrate into the solar cell, maximizing photovoltaic conversion efficiency. At the same time, Polyvinyl butyral PVB reduces light reflection and improves the panel’s ability to capture light.

Mechanical Protection

Due to the toughness and elasticity of PVB polyvinyl butyral, polyvinyl butyral film provides a cushion against physical impacts on the panel, preventing cell breakage. This protection is especially important for panels installed in environments that are susceptible to wind, rain, or other physical impacts.

Application Flexibility

The processing and application flexibility of PVB allows it to be cut into different sizes and shapes to fit a variety of specification solar panel designs. This characteristic makes PVB ideal for many types and designs of solar projects.

PVB is used in solar panels not only as a physical barrier, but also to improve the overall performance and durability of solar panels through its unique physical and chemical properties. By using PVB polyvinyl butyral binder, solar panel manufacturers are able to provide more reliable and efficient solar solutions.

Comparison of EVA and PVB

EVA is also a commonly used material in solar modules.

EVA Film in Solar Packaging

EVA film was introduced in the 1980s. It is a hot-melt adhesive film that is non-stick at room temperature and has good mechanical properties. These properties make it a suitable material for solar cell packaging and outdoor use.

Differences between EVA and PVB

Areas of application

EVA is used for the encapsulation of crystalline silicon cells. EVA films are also used for the intrinsic protection and interlayer bonding of cells and photovoltaic cell cover glass panels.

Polyvinyl butyral interlayer is mainly used in thin-film batteries, double-glazed building-integrated photovoltaic (BIPV) modules, etc. PVB materials are produced by different companies. PVB materials are produced by a variety of companies, including DuPont and Kuraray.

Lamination processes for EVA and PVB

Both EVA and PVB have different temperature requirements, as each material requires a specific range. EVA has good thermoplasticity and the material requires a room temperature range. PVB polyvinyl butyral has higher temperature requirements (around 155°C), which is considered high for laminators.

Other differences

There are many other differences between PVB and EVA, including the fact that PVB is a construction material, so it has a very good gas barrier and very good adhesive properties, as well as better weathering properties.

The main disadvantage of PVB is the poor water vapor barrier, which can cause many problems in solar cells.

When laminates are exposed to moisture or water for long periods of time, it is not recommended to use a regular PVB interlayer, as delamination may occur over time.

Polyvinyl butyral PVB has lower mechanical properties than EVA and a more difficult manufacturing process. Another factor is the cost of the two materials.

PVB polyvinyl butyral binder is more economical than EVA, which is more than three times as expensive.

| Attribute | EVA | PVB |

| Cost | Less expensive compared to PVB. | More expensive than EVA, but offers significant material advantages. |

| Gas Barrier | Lower gas barrier performance, more susceptible to gases. | Excellent gas barrier performance, effectively blocks gases. |

| Adhesion | Good adhesion but less effective than PVB. | Superior adhesion properties, which is crucial for longevity and durability. |

| Weather Resistance | Offers decent weather resistance but not as robust as PVB. | Excellent weather resistance, suitable for harsher environmental conditions. |

| Moisture Barrier | Generally performs well, but not as effective as PVB in preventing moisture ingress. | Poor moisture barrier; potential for delamination when exposed to moisture for extended periods. |

| Mechanical Strength | Generally strong but mechanically weaker than PVB. | Mechanically weaker than EVA, making handling and processing more challenging. |

| Processing Difficulty | Easier to handle and process due to its thermoplastic nature. | More difficult to process due to higher temperature requirements and mechanical properties. |

In today’s rapidly growing solar industry, PVB offers a potentially high-value solution for panel encapsulation. As the demand for renewable energy continues to grow and technology advances, the use of PVB is expected to become even more widespread, with further environmental and economic benefits.

It is only through continued innovation and improvement that we can ensure solar technology is at the center of future energy solutions and contribute to a cleaner, greener global energy system.